The drying course of action is inversely proportional to the air humidity. For more quickly drying, the humidity need to be at a least. Humidity may be diminished by generating the particle size tiny because of less inside diameter.

At higher temperature, the particle absorbs more heat for evaporation and growing evaporation level As well as in minimal temperature, fewer heat is absorbed plus the evaporation charge is lowered.

Hybrid Fluidized Mattress Dryers: These dryers Merge options of fluidized mattress and other sorts of dryers, which include tray dryers or rotary dryers.

Vertical FBD is the most generally made use of dryer during the pharmaceutical sector and is straightforward and straightforward to operate and maintain.

Drying procedures are of huge great importance in many different industries – such as food stuff, pharmaceutical, and chemical – due to their power to minimize the dampness written content in components.

Frequent maintenance and cleansing of the fluidized mattress equipment are essential to make sure its efficient Procedure.

HEAT EXCHANGERS; The gear useful for warmth transferring are often called heat exchangers. A lot of the procedures that entails warmth transfer in pharmaceutical industries are: Preparing of starch paste (in steam jacketed kettle). Crystallization. Evaporation. Distillation. Classification of heat exchangers On The idea of transfer of warmth, warmth exchangers are labeled as: Immediate transfer type: The hot and cold fluids are divided by a metal wall by which the heat is transferred from incredibly hot fluid to cold fluid. E.g. shell and ...

The baggage used below Have got a finger-like framework which can help increase the surface area location on the drying bed. This kind of structure helps improve the drying amount and reduce read more the drying time in the fluid mattress drying process.

Fluid mattress dryers use higher levels of warm fuel and air Consequently rendering it challenging to dry poisonous or flammable components.

Thoroughly clean the sampling port and mesh with potable h2o accompanied by nylon scrubber dipped in potable h2o to remove the traces of previous supplies.

The newest tendencies and innovations in Fluidized Bed Dryer technological innovation are definitely the Vitality Efficiency Reigns by Waste warmth seize, optimized airflow, and hybrid drying with microwaves slash energy intake, Automation with true-time monitoring and AI Handle guarantees merchandise good quality and minimizes operator demands, Integrated Drying, coating, granulating and Pelletizing course of action in one device boost effectiveness and lower managing and versatile configurations adapt to diverse resources and output scales, maximizing versatility.

a particle. This product can be made use of when any rotational consequences are zero or don't have any desire even though the body by itself may be extended. The human body can be represented by a small symbolic blob and the diagram lowers to the set of concurrent arrows. A drive with a particle is a bound vector.

Begin-up: The FBD is begun, plus a stream of preheated website air is released to the drying chamber from The underside. The velocity in the air is very carefully controlled to initiate fluidization without the need of entraining too many particles.

A fluidized mattress dryer can be a smartly built industrial device used to competently dry the moist powders, granules or solid particles by suspending through the use of inlet sizzling air flow. In this process, the solid materials creating a state where the particles exhibit fluidized point out.

Alicia Silverstone Then & Now!

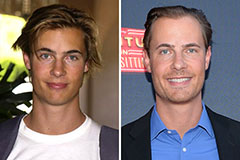

Alicia Silverstone Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Batista Then & Now!

Batista Then & Now! Barbara Eden Then & Now!

Barbara Eden Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!